This page has instructions on how to replace the front endbell and rotor/shaft on Castle sensored motors.

Note:

Replacement rotors for 17xx and 20xx series motors are not

available. These parts are not serviceable and cannot be repaired or

replaced. If the rotor is broken or the shaft is bent the entire motor must be replaced.

Replacing front endbell

1. Remove front endbell screws using a 2.5mm hex wrench.

2. Pull damaged endbell away, keeping shaft vertical. There is a brass shim and wave washer on the shaft, do not lose these.

Note: Rotating endbell may help break it free if stuck.

3. Replace with the new endbell. The rotor will be magnetically attracted to the stator, so you may need to push the endbell/shaft around to seat the new endbell

4. Apply a small amount of removable threadlocker (IE Blue LocTite) to threads of the new screws and torque until snug.

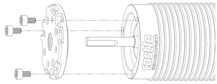

Front endbell example

Replacing rotor/shaft

CAUTION: Motor magnets are very powerful and are a pinch hazard. Use caution when handling the rotor. The rotor can be damaged it magnetically smacks into a ferrous material.

Removing old rotor/shaft.

1. Remove front endbell screws using a 2.5mm hex wrench.

2. Remove endbell from motor can, keeping shaft vertical.

Note: Rotating endbell may help break it free if stuck.

3. Locate and remove brass shim and wave washer.

4. Using pliers, with shaft facing sideways or down, grab output shaft and pull old rotor from can.

Note: There is a second brass spacer at the back of the rotor, remove this.

Installing new rotor/shaft

5. Install one of the new brass shims to back of motor.

6. With opening facing down (wires at top), carefully slide the new rotor into the motor can. Ensure rear brass spacer stays on shaft and rotor seats into rear bearing.

7. Flip motor over so shaft faces up. Install new wave washer and brass spacer. The wave washer should be toward the rotor (magnet), the brass spacer should be on top.

8. Reinstall endbell. The rotor will be magnetically attracted to the stator, so you may need to push the endbell/shaft around to seat the new endbell

9. Apply a small amount of removable threadlocker (IE Blue LocTite) to threads of the three screws and torque until snug.

Exploded view of motor internals

Exploded view of motor parts.